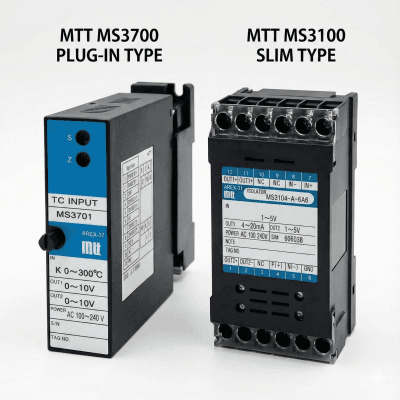

MTT Signal Conditioner Selection Guide: MS3100 vs. MS3700 vs. MS3000

Running out of space in your control panel? Selecting the right signal conditioner is about more than just converting 4-20mA signals. It is about panel space, wiring efficiency, and ease of maintenance. At Celectric Sdn Bhd, we specialize in MTT (Ms. System) signal conditioners from Japan. However, engineers often ask us: “What is the difference […]

MTT Signal Conditioner Selection Guide: MS3100 vs. MS3700 vs. MS3000 Read More »