The Contrec 515 BT01 is a reliable dual-stage batch controller designed for the precise delivery of preset amounts of petroleum and other liquids. It features a frequency flow input that can accept a quadrature signal, ensuring ISO 6551 level B pulse security. Additionally, it has temperature and density inputs that allow for volume correction to standard reference conditions.

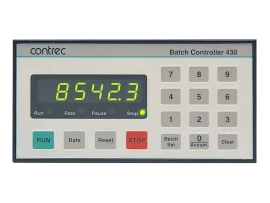

This industrial dosing pump controller can be configured to require a valid ID-Tag and/or a Permissive input before starting a delivery. The ID-Tag number is recorded as part of the transaction log, making it easy to connect deliveries to external databases.

It supports a variety of fluid types, including different crude and refined petroleum products. For other general fluids, temperature compensation can be achieved using a thermal expansion coefficient or a user-defined table.

CALCULATIONS

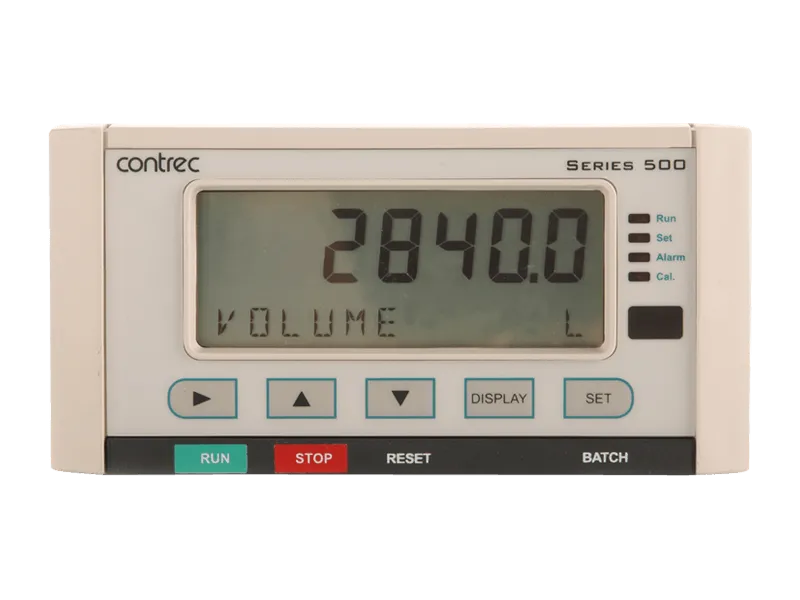

The total gross volume and flow rate are calculated from accurately measured frequency and the number of received pulses.

Volume = pulses / k-factor

Volume flow = frequency / k-factor

Volume correction calculations follow the ASTM D1250-04 and API Table 54 standards for the following products:

- Crude Oils

- Lube Oils

- Refined Products

- Light Hydrocarbon Liquids (LPG)

For other fluids, volume correction can be calculated using:

- General Coefficient of Expansion

- Preprogrammed User Table