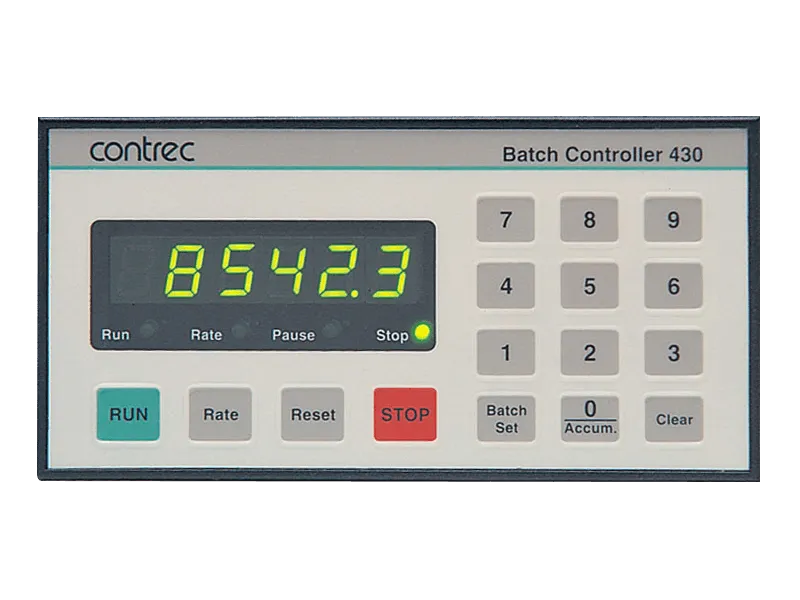

The Contrec 430D Batch Controller offers exceptional flexibility and user-friendly operation. It allows for easy control of batches with four operational keys, and batch quantities and calibration parameters can be entered using a 12-key numeric keypad. The green LED display shows Batch Total, Flow Rate, Accumulated Total, and Preset Value in engineering units. The controller accepts various pulse signals and frequencies, including mV outputs from turbine flowmeters and two-wire proximity switch outputs. Additionally, it automatically compensates for any overrun caused by slow closing valves based on previous batches.

Printer or Computer Interface

The controller can be equipped with an RS442/485 and RS232 option for printer and computer interface. This interface enables full control of the 430D Batch Controller from a computer. Software drivers are included for certain printers, allowing for ticket printing with time and date, sequential delivery, batch number, and batch and accumulated totals. An optional header for the ticket can also be printed.

Flow Totalizer Mode

The 430D can be configured to function as a Flow Rate Totalizer separate from a batch controller. In this mode, the RUN, STOP, and Batch Set keys have no function. The Rate key toggles the display between Rate and Resettable Total. The Accumulated Total can be viewed by pressing and holding the Accum key when the instrument is not in data entry mode.

Versatile Performance Options

The controller operates on 14 to 28V DC or 110 to 220V AC mains power. Its front panel is fully waterproof to NEMA 4X (IP65) standards and resistant to chemicals. The total conversion feature allows the rate to be displayed in one engineering unit (e.g., gallons/minute) and the totals in another engineering unit (e.g., barrels). The standard instrument is panel mountable, with field enclosures available as an option. The simple keypad operation and four LED indicators provide clear operational status at all times. The four operational keys and full numeric keypad on the front display enable easy batch quantity setting and control operations such as starting, pausing, stopping, or resetting batches.

Batch Quantity Set

To set the batch quantity, press the Batch Set key and enter the desired value using the numeric keys. Press the Batch Set key again to return to the Run mode. The batch quantity can only be set when the instrument is not operational, such as when the batch is complete or paused. Once set, the batch quantity is stored in non-volatile memory and remains unchanged until modified by the user. To check the batch quantity during a batch in progress, press the Batch Set key.

Starting a Batch

Press the RUN key to begin the batch. The Run LED will illuminate, and the instrument will start totaling from zero or decrement from the batch quantity if programmed in countdown mode.

Stopping a Batch

The batch can be stopped at any time by pressing the STOP key. To continue the batch, press the RUN key, or press the STOP key again to abort the batch. When the batch is interrupted, the Pause LED will illuminate. If the batch is aborted, the Stop LED will illuminate.

Resetting a Batch

The instrument can be programmed for two types of resets. Manually pressing the Reset key will reset the Batch Total to zero (for count-up mode) or to the preset quantity (for count-down mode). Alternatively, if Auto Reset is programmed, the Batch Total will automatically reset when the RUN key is pressed.

Single or Two-Stage Valve Control

Two output relays provide control for single or dual-stage valve operation. The first relay energizes as pre-start and de-energizes when the batch is complete. The second relay can be programmed to enable slow-start or slow-stop by setting the time or quantity before completing the batch. This feature allows for a