Selecting the wrong pressure reference (Gauge vs. Absolute) is the #1 cause of sensor error in industrial applications.

In this guide, we break down the three main types of pressure measurement—Gauge, Absolute, and Differential—and help you select the correct sensor for HVAC, Hydraulics, and Process Control.

The Quick Selection “Cheat Sheet” Want the answer fast? Use this table to match your application to the right sensor type.

| Pressure Type | Reference Point | Common Applications | Recommended Sensor |

| Gauge (PSIG) | Atmosphere (14.7 psi) | Hydraulics, Pumps, Tyres, Open Tanks | Gems 3100 Series |

| Absolute (PSIA) | Perfect Vacuum (0 psi) | Vacuum Packaging, Barometers, Weather | Setra Model 204 |

| Differential (PSID) | Process Pressure B | Filter Status, Flow Rate, Liquid Level | Setra 261C |

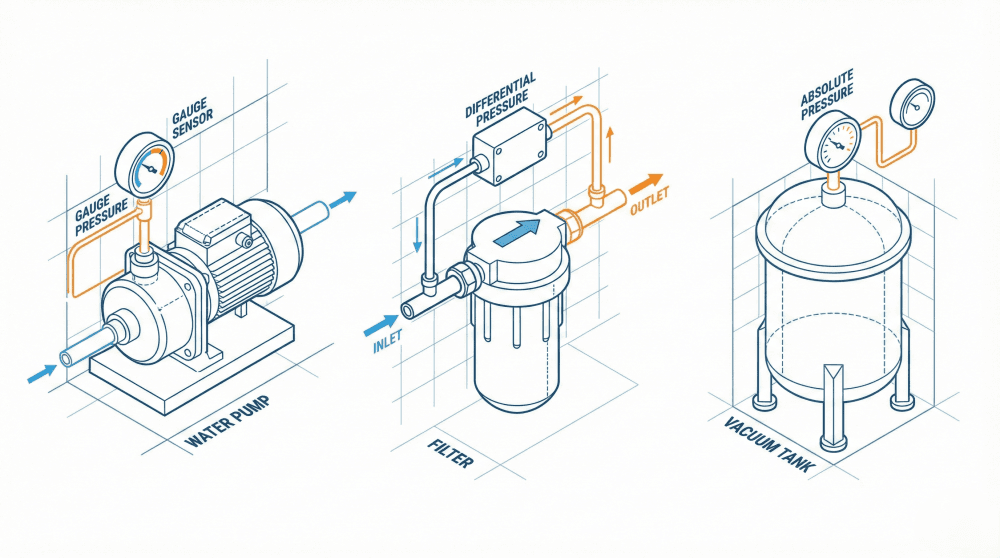

Gauge Pressure (The Industry Standard)

Most industrial pressure transmitters measure Gauge Pressure. This uses the ambient atmosphere as the reference point.

How it works: The sensor has a small vent that allows air to enter the back of the diaphragm. If the barometer changes, the sensor adjusts automatically.

When to use it: Anytime you are measuring pressure “relative to the room,” such as water pump discharge or hydraulic oil pressure.

💡 Expert Recommendation: For heavy-duty hydraulic or water applications (up to 2,200 bar), we recommend the Gems 3100 Series. It features a sputtered thin-film sensor for high shock resistance.

Absolute Pressure (Vacuum & Sealed Systems) Absolute Pressure

is measured against a perfect vacuum. It does not change with the weather or altitude.

When to use it:

Vacuum Packaging: To ensure all air is removed.

Barometric Monitoring: Measuring atmospheric pressure itself.

Sealed Tanks: Where outside air pressure shouldn’t affect the reading.

💡 Expert Recommendation: For high-accuracy vacuum measurement, look for the [Setra Model 204] or [Setra 270], which provide stable readings down to 0 PSIA.

Differential Pressure (Comparing Two Points) Differential Pressure (DP) measures the difference between two ports (High Port vs. Low Port). It ignores the system’s static pressure.

Common Use Case: Monitoring an Air Filter.

If the filter is clean, pressure is equal on both sides (DP = 0).

If the filter is clogged, pressure drops on the outlet side, causing DP to rise.

💡 Expert Recommendation:

For Cleanrooms/HVAC: Setra 261C (Low pressure, high accuracy).

For Filter Monitoring: Dwyer Magnehelic / Magnesense

How to Select a Pressure Sensor (4-Step Checklist)

Before you buy, check these 4 specs to ensure compatibility:

Pressure Range: Choose a range where your normal operating pressure is around 60-80% of the full scale. (e.g., If your pump runs at 60 psi, buy a 100 psi sensor).

Output Signal:

4-20mA: Best for long distances and noise immunity (PLCs).

0-10V: Common in Building Automation (BMS).

Wetted Materials:

Stainless Steel (316L): Standard for water, oil, and gas.

Brass: Low-cost option for benign fluids.

Process Connection: Standard sizes in Malaysia are 1/4″ NPT or G 1/4″ (BSP). Ensure you order the correct thread.

Need help specifying a sensor? Our engineering team in Penang can help you select the exact Gems or Setra model for your machine. WhatsApp us for a Quote or View All Pressure Sensors