The Precision Digital Trident PD765 digital panel meter is one of the most versatile meters on the market and will satisfy a wide variety of process and temperature applications. Housed in a 1/8 DIN enclosure with a NEMA 4X front, the meter can be field programmed to accept process voltage (0-5 V, 1-5 V, etc.) and current (4-20 mA) inputs, 100 Ohm RTDs, and the four most common thermocouples.

The display height on the standard Trident meter is 0.56″ (14.2 mm), and on the Trident X2, the display height is an astounding 1.2″ (30.5 mm). The intensity of the display can be adjusted to compensate for various lighting conditions, including direct sunlight. Programming and setup can be performed with the four front panel pushbuttons, free MeterView software, or using the copy function. Options for the PD765 include two relays, a 4-20 mA output, 24 V transmitter power supply, and Modbus® serial communications.

General

Display: Trident: 0.56” (14.2 mm); Trident X2: 1.20” (30.5 mm) red LED, 4 digits (-1999 to 9999)

Display Intensity: Eight user selectable intensity levels

Front Panel: NEMA 4X, IP65; panel gasket provided

Programming Methods: Four front panel buttons, cloning with Copy feature, PC with MeterView or LabVIEW software, and Modbus registers. Certified LabVIEW driver available.

Noise Filter: Programmable 2 to 199 (0 will disable filter)

Display Update Rate: Process/RTD: 3.7-5/sec; TC: 1.8-2.5/sec

Overrange: Display flashes 9999

Underrange: Display flashes -1999

Recalibration: All inputs are calibrated at the factory; recalibration is recommended at least every 12 months.

Max/Min Display: Stored until reset by user or meter is turned off.

Password: Restricts modification of programmed settings.

Non-Volatile Memory: Settings stored for a minimum of 10 years.

Power Options: 85-265 VAC, 50/60 Hz; 90-265 VDC, 20 W max or 12-36 VDC; 12-24 VAC, 6 W max.

Required Fuse: UL Recognized, 5 A max, slow-blow; up to 6 meters may share one fuse.

Normal Mode Rejection: 64 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line; 500 V input-to-output or output-to-24 VDC supplies.

-6R5 & -6X5 skus only: 100 V output-to-24 VDC supply

Operating Temperature: -40 to 65°C

Storage Temperature: -40 to 85°C

Relative Humidity: 0 to 90% non-condensing

Connections:

Power & Signal: removable screw terminal blocks accept 12 to 22 AWG.

Serial: RJ11 header, standard on all meters.

Enclosure: 1/8 DIN, high impact plastic, 94V-0, color; gray

Weight: 9.5 oz (269 g) (including options)

UL File Number: E160849; 508 Industrial Control Equipment

Warranty: 3 years parts & labor

Process Inputs

Inputs: Field selectable: 0-20 mA, 4-20 mA, 1-5 V, ±10 V

Accuracy: ±0.05% FS ±1 count; square root: ±0.1% FS ±2 counts

Function: Linear or square root

Low-Flow Cutoff: 0 to 9999 (0 disables cutoff function)

Decimal Point: Up to 3 decimals: d.ddd, dd.dd, ddd.d, or dddd

Calibration: Scale without signal or calibrate with signal source

Calibration Range: User programmable over entire range of meter

Input Impedance: Voltage range: greater than 1 M Ω, Current Range: 50-100 Ω, varies with resettable fuse impedance

Input Overload: Protected by automatically resettable fuse

Temperature Drift:

| 0 to 65°C ambient | -40 to 0°C ambient |

| Current: ±0.20% FS (50 PPM/°C) | Current: ±0.80% FS |

| Voltage: ±0.02% FS (1.7 PPM/°C) | Voltage: ±0.06% FS |

Transmitter Supply: Isolated, one or two transmitter supplies

P1: 24 VDC ±10% @ 200 mA max (-1 option)

P1 & P2: 24 VDC ±10% @ 200 mA & 40 mA max (-2 option)

Temperature Inputs

Inputs: Factory calibrated, field selectable: type J, K, T, or E thermocouples and 100 Ω platinum RTD (0.00385 or 0.00392 curve)

Resolution: 1°; type T: 1° or 0.1°

Cold Junction Reference: Automatic

Temperature Drift: ±2°C maximum

Offset Adjustment: Programmable to ±19.9°. This parameter allows the user to apply an offset value to the temperature being displayed.

Input Impedance: Greater than 100 k Ω

Sensor Break: All relays and alarm status LEDs go to alarm state.

| Input Type | Range | Accuracy

(0-65° C) | Accuracy

(-40-0° C) |

| Type J | -58° to 1382° F

-50° to 750° C | ±2° F

±1° C | ±5° F

±3° C |

| Type K | -58° to 2300° F

-50° to 1260° C | ±2° F

±1° C | ±4° F

±2° C |

| Type T | -292° to 700° F

-180° to 371° C | ±2° F

±1° C | ±13° F

±7° C |

Type T

0.1° Res | -199.9° to 700.0° F

-180.0° to 371.0° C | ±1.8° F

±1° C | ±13° F

±7.2° C |

| Type E | -58° to 1578° F

-50° to 870° C | ±2° F

±1° C | ±11° F

±6° C |

| 100 Ω RTD | -328° to 1382° F

-200° to 750° C | ±1°F

±1° C | ±5°F

±3° C |

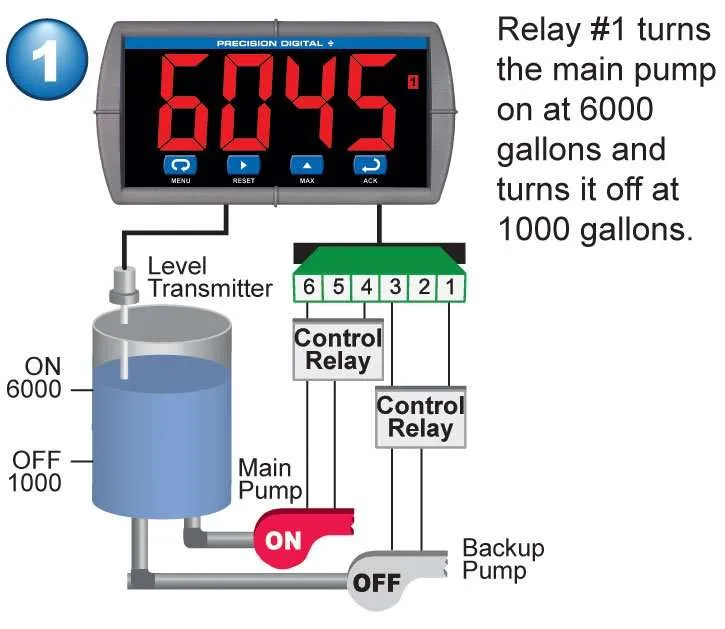

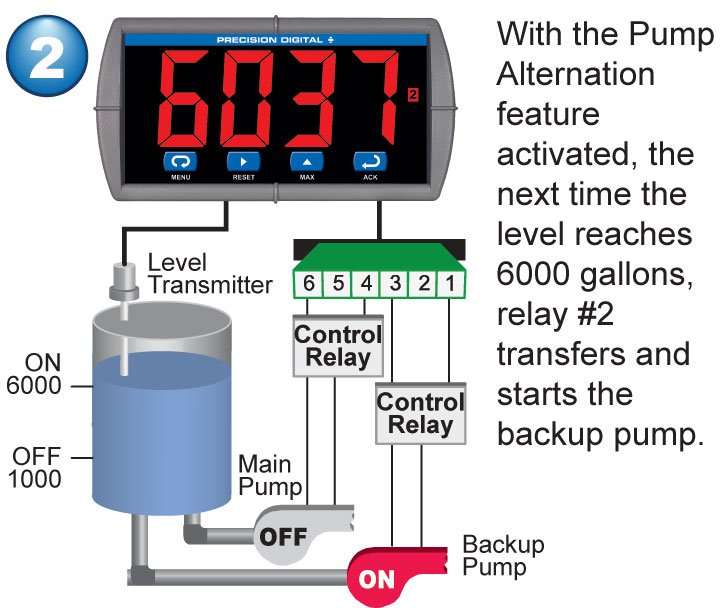

Relays

Rating: 2 Form C (SPDT); rated 3 A @ 30 VDC or 3 A @ 250 VAC resistive load; 1/14 HP @ 125/250 VAC inductive loads

Deadband: 0-100% FS, user selectable

High or Low Alarm: User may program any alarm for high or low

Relay Operation:

- Automatic (non-latching)

- Latching

- Pump alternation control

Relay Reset: User selectable via front panel buttons or PC

- Automatic reset only (non-latching)

- Automatic plus manual reset at any time (non-latching)

- Manual reset only, at any time (latching)

- Manual reset only after alarm condition has cleared (latching).

Automatic Reset: Relays reset when input passes the reset point

Manual Reset: Front panel button, MeterView, Modbus registers

Time Delay: 0 to 199 seconds, on and off delays; programmable

Fail-Safe Operation: Programmable, independent for each relay. Relay coils are energized in non-alarm condition. In case of power failure; relays will go to alarm state.

Auto Initialization: When power is applied to the meter, relays will reflect the state of the input to the meter.

Isolated 4-20 mA Transmitter Output

Scaling Range: 1.00 to 23.00 mA; reverse scaling allowed.

Calibration: Factory calibrated 4.00 to 20.00 mA

Accuracy: ±0.1% FS ±0.004 mA

Temperature Drift: 50 PPM/°C

Note: Analog output drift is separate from input drift

Isolation: 500 V input-to-output or output-to-24 VDC supplies; 4 kV output-to-power line

External Power: 35 VDC maximum

Output Loop Resistance:

| Loop Resistance |

| Power Supply | Minimum | Maximum |

| 24 VDC | 10 Ω | 700 Ω |

| 35 VDC (external) | 100 Ω | 1200 Ω |

Serial Communications

Compatibility: EIA-232, EIA-422, and EIA-485 with PDA7232 and PDA7422 Trident adapters.

Protocol: Two selectable. PDC protocol (for use with MeterView) and Modbus RTU

Meter Address: PDC protocol: 0 to 99, Modbus protocol: 1 to 247

Baud Rate: 300 to 19,200 bps

Transmit Time Delay: Programmable 0 to 199 ms or transmitter always on for RS-422 communications.

Data: 8 bit (1 start bit, 1 stop bit)

Parity: None (2 stop bits), even, or odd

(Modbus only; PDC protocol does not use parity)

Byte-to-Byte Timeout: 0.01 to 2.54 seconds (Modbus only)

Turn Around Delay: Less than 2 ms (fixed)

Refer to PDC and Modbus Serial Communications Protocol manuals for details.

Note: Both downloadable protocol register tables can be found in the documentation list below.

Application

Pump Alternation

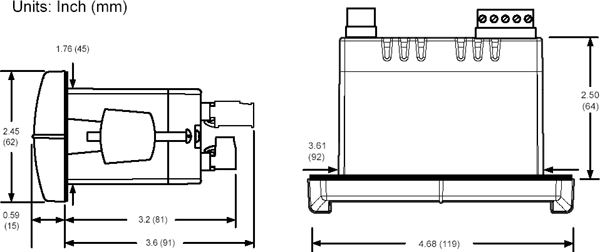

Mounting Dimensions

Notes:

- Panel cutout required: 1.772″ x 3.622″ (45 x 92 mm)

- Panel thickness: 0.040″ – 0.250″(1.0 – 6.4 mm)

- Mounting brackets lock in place for easy mounting

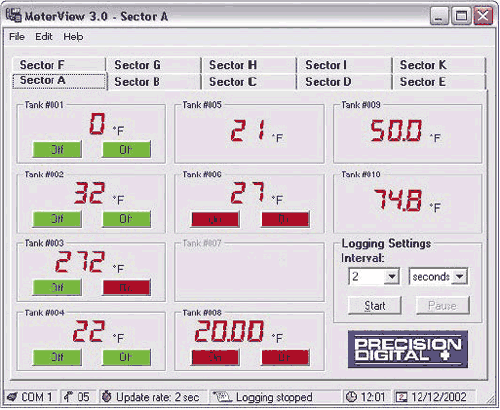

MeterView® for Trident

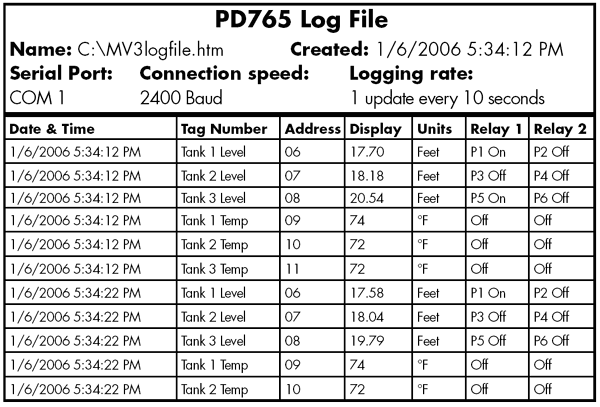

MeterView software allows remote programming and data acquisition of the Trident series. The remote programming allows for all available meter settings to be programmed from a personal computer through an easy user-friendly interface. The data acquisition allows the user to gather readings from up to 100 meters at user-selected intervals and generate charts using common tools like Microsoft® Excel.

Digital Panel Meters make a great front end to a PC-based data acquisition system. They are easy to set up, can be used for a wide range of inputs, will power the transmitter, and best of all provide a local display of the process. Precision Digital has the perfect package with its Trident Digital Panel Meters, a wide selection of serial adapters and converters and free MeterView software. Data is displayed on the PC and written to a file that could then be imported into a spreadsheet or other application.

Data Logging up to 100 Trident Meters

Sample File Generated by MeterView®

Great for tank level monitoring!

Ordering Example: System consisting of 10 Tridents & MeterView

| Qty | Model | Description |

| 10 | PD765-6R2-10 | Trident with 2 Relays & 24 VDC Transmitter Supply |

| 10 | PDA7422 | Trident RS-485 Serial Adapter |

| 1 | PDA8485-I | USB to RS-422/485 Isolated Converter |

| 1 | PDA7503-2 | MeterView Software for 1-10 Meters |