A Batch Controller is a process instrument that automates the dispensing of a precise volume of liquid.

Unlike a simple flow totalizer (which only counts), a Batch Controller actively controls a valve or pump via relays. It opens the valve, counts the flow pulses, and closes the valve exactly when the target volume is reached.

Choosing the wrong control method causes “Hammer Effect” or inaccurate dosing. Use this table to decide.

| Control Type | How It Works | Best Application |

| Single Stage | Valve opens fully -> Valve closes instantly at target. | Small pipes, slow flow, non-critical dosing. |

| Dual Stage | Valve opens fully, then slows down to 90%, and closes gently. | High Speed Filling, Chemical Drums, Large Tanks. Prevents “Water Hammer.” |

Recommendation: For most industrial filling lines in Malaysia, we recommend Dual Stage control using the Contrec 424 Batch Controller to ensure high accuracy.

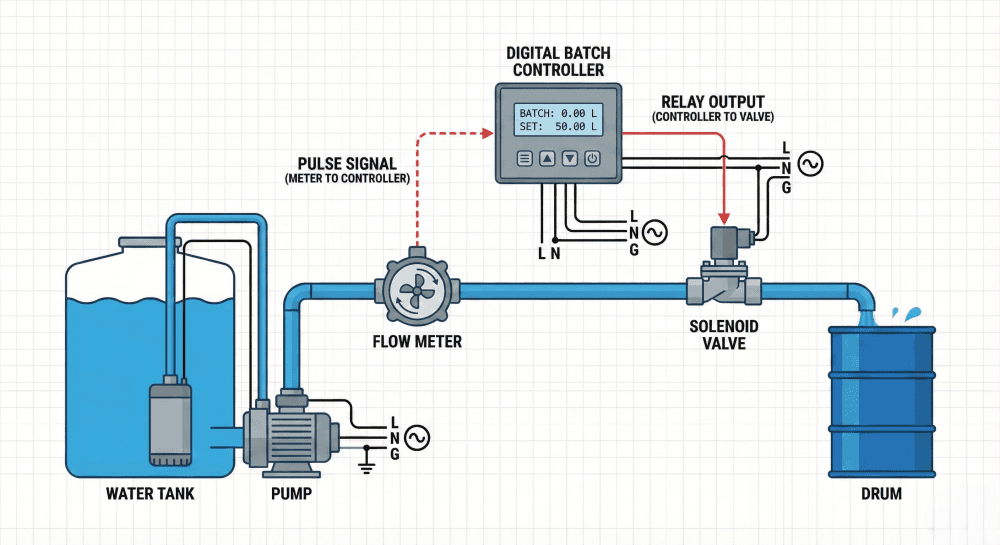

To build a complete Batching System, you need 3 components:

The Flow Meter: Generates pulses (e.g., [Contrec Flow Meter] or Mag Meter).

The Batch Controller: The “Brain” that counts pulses and controls the relay.

The Control Valve: A solenoid or pneumatic valve connected to the relay output.

Troubleshooting Common Issues

Overrun (Too much liquid): Your valve is closing too slowly. Adjust the “Pre-Act” or “Overrun” setting on your Contrec 414 to close the valve before the target is reached.

Missing Pulses: Check your flow meter grounding. Electrical noise can cause the controller to miss signals.

Recommended Models

For Standard Dosing: Contrec 424 Batch Controller (The industry workhorse).

For Hazardous Areas: Contrec 214D (Intrinsically Safe)

For Ratio Blending: Contrec 515-BR01 (Mixes two liquids automatically).