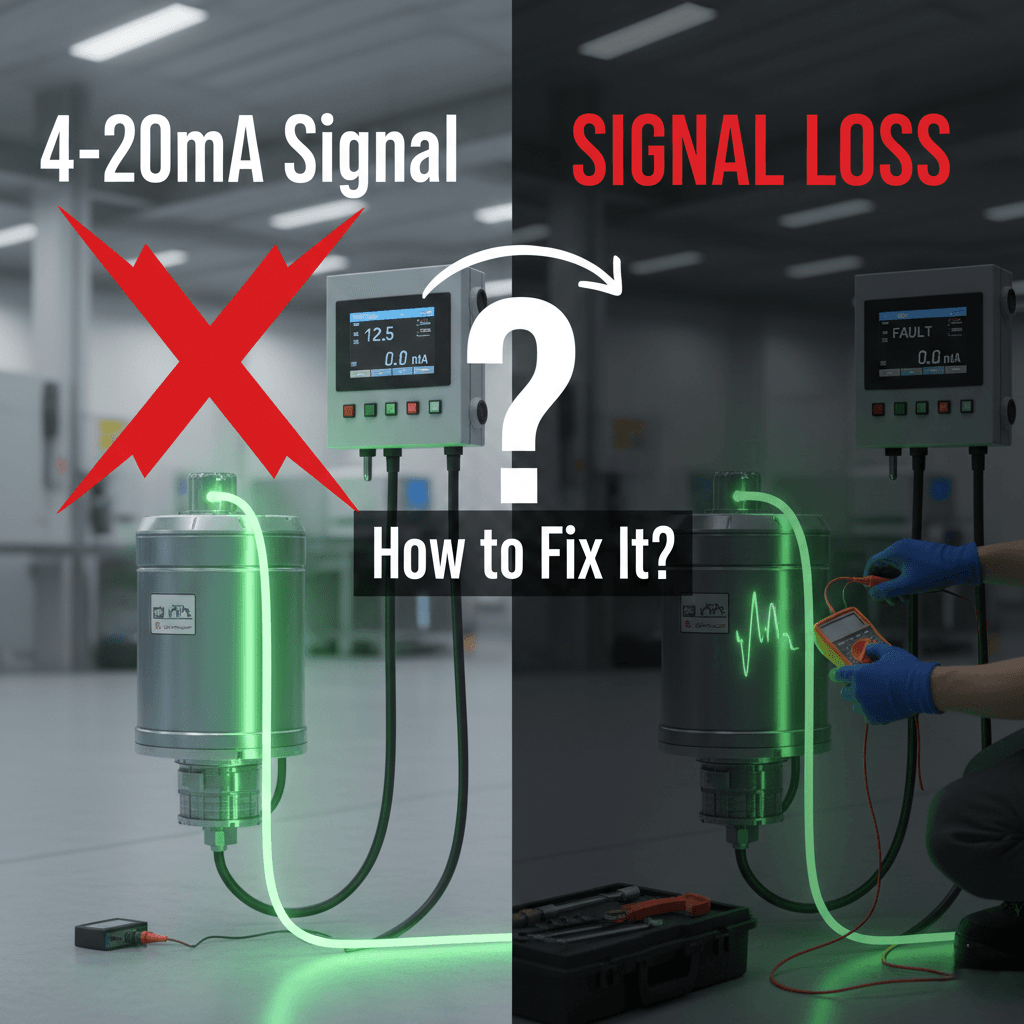

If your digital panel meter suddenly shows zero, your PLC input flatlines, or your sensor stops responding, chances are — you’re facing a 4–20mA signal loss.

This is one of the most common troubleshooting issues in factories, refineries, and automation plants. Let’s break it down in simple terms and show you how to fix it fast.

What Is a 4–20mA Signal?

The 4–20mA current loop is the industry standard for sending analog signals from transmitters to controllers, indicators, or PLCs. It converts physical measurements like pressure, level, temperature, or flow into a simple current signal.

4mA = minimum reading (e.g. 0 bar)

20mA = maximum reading (e.g. 10 bar)

✅ Stable and reliable even over long cable runs

✅ Immune to voltage drop and electrical noise

✅ Works well in Malaysia’s humid, high-interference environments

What Is “Signal Loss”?

Signal loss happens when the current loop is broken or interrupted, meaning the receiver is no longer getting any signal from the transmitter.

Typical symptoms:

Display reads “0.00” or blank

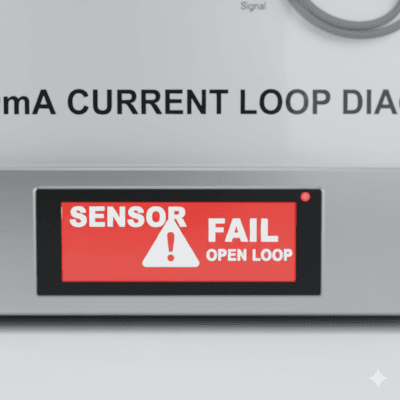

PLC alarm says “no signal” or “sensor fail”

Control system triggers unexpected shutdowns or interlocks

Top 5 Causes of 4–20mA Signal Loss (Common in Malaysia)

1. Broken or Disconnected Wires

Heat, vibration, and moisture in factory environments can damage or loosen cables.

Fix: Inspect terminals and use a multimeter to test for continuity.

2. Power Supply Failure

Most transmitters need a stable 24VDC power source. If the power supply fails, your sensor won’t output any current.

Fix: Verify 24VDC with a multimeter before checking the sensor.

3. Overloaded Current Loop

Connecting too many instruments in one loop can cause voltage drop and signal loss.

Fix: Calculate total loop resistance and ensure your power supply capacity matches.

4. Incorrect Wiring or Polarity

Reversed polarity or wrong terminals can cause total signal failure — or even damage.

Fix: Refer to your sensor wiring diagram and check the +/– connections carefully.

5. Sensor or Transmitter Failure

After years of service — especially outdoors or in humid sites — sensors may fail internally.

Fix: Replace with a new or equivalent model. Celectric can help with cross-referencing and local stock support.

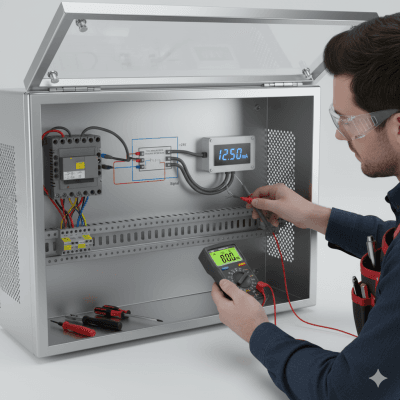

Recommended Tools for Troubleshooting

Multimeter (set to mA or voltage mode)

Loop calibrator or signal simulator

Spare transmitter for swap testing

Pro Tip from Our Celectric Engineers

When troubleshooting 4–20mA signal loss, always check in this order:

Power supply (24VDC)

Wiring continuity

Sensor/transmitter health

In 70% of site cases, the root cause is loose wiring or power supply failure, not the sensor itself.

At Celectric, we supply and support:

4–20mA pressure, level, flow, and temperature transmitters

Panel meters, signal isolators, and loop-powered instruments

On-call technical support to identify and solve signal loss issues quickly

📞 Call or WhatsApp Celectric if your Gems, Setra, Finetek, or Contrec sensor is acting up — we’ll help you troubleshoot and source replacements fast.

Related Products You Might Need

Signal Isolators – reduce noise and prevent interference

Digital Panel Meters – brands like Adtek, Precision Digital

Loop-Powered Transmitters – Gems, Finetek, Anderson-Negele