The Precision Digital PD6700 Vantageview is a robust loop-powered process and level meter, crafted for challenging industrial settings. Its tough NEMA 4X/IP65-rated enclosure guarantees dependable performance even in wet or dirty conditions, making it an excellent choice for harsh environments. The meter features a large, high-contrast LCD display that makes it easy to read process data, and it offers an optional bar graph for level indication. Additionally, the PD6700 includes SafeTouch® technology, allowing for safe programming through the window without needing to remove the cover.

Key Features:

- High-Visibility Display: The 5-digit upper display shows process variables, while the 7-character lower display can show flow totals or tags. The optional bar graph serves as a clear level indicator.

- SafeTouch® Technology: This feature allows for secure button programming through the window, enabling configuration without exposing the internal electronics.

- NEMA 4X/IP65 Enclosure: This protective casing shields the meter from water, dust, and other environmental factors, ensuring durability and longevity.

- Wide Operating Range: The PD6700 functions effectively in extreme temperatures, from -40 to 75°C, making it suitable for various industrial applications.

- Flexible Installation: With a rotatable display, three conduit connections, and options for wall or pipe mounting, installation is versatile and adaptable.

Applications:

- Flow Measurement: Perfect for tracking flow rates in industrial processes.

- Level Monitoring: The optional bar graph level indicator is ideal for monitoring levels in tanks and vessels.

- Process Control: Essential for various industrial processes that require accurate and reliable monitoring of process variables.

The Precision Digital PD6700 is your go-to solution for monitoring process variables and level measurements in demanding industrial environments. With its user-friendly interface, rugged construction, and flexible installation options, the PD6700 ensures reliable performance where it counts the most.

General

Display: Upper: Five digits (-9999 to 99999) 0.70″ (17.8 mm) high, 7-segment, automatic lead zero blanking;

-0L1: 0.6″ high with level bar graph. Lower: Seven characters 0.4″ (10.2 mm) high, 14 segment alphanumeric. Symbols: for high & low alarm, Password Lock. Backlight: White

Decimal Point: Upper process display has up to four decimal places or none: d.dddd d.ddd, d.dd, d.d, or ddddd

Display Update Rate: Ambient > -25°C: 2 Updates/Second. Ambient < -25°C: 1 Update/5 Seconds

Display Orientation: Display may be mounted at 90° increments up to 270° from default orientation.

Overrange: Display flashes 99999

Underrange: Display flashes -9999

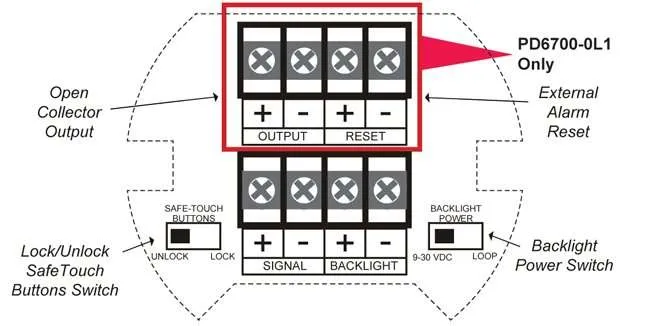

Programming Method: Four SafeTouch® through-window buttons when cover is installed. Four internal pushbuttons when cover is removed.

Noise Filter: Programmable – Lo, Med, Hi, or Off

Recalibration: Recalibration is recommended at least every 12 months.

Max/Min Display: Max/Min readings reached by the process are stored until reset by the user or until power to the meter is turned off.

Password: Programmable password restricts modification of programmed settings.

Advanced Functions: Live input calibration, linearization, square root, or programmable exponent

Alarm Indication: Flashing display plus HI/LO indicators

Non-Volatile Memory: All programmed settings are stored in non-volatile memory for a minimum of ten years if power is lost.

Normal Mode Rejection: 64 dB at 50/60 Hz

Operating Temperature Range: -40 to 75°C.

Storage Temperature Range: -40 to 75°C.

Relative Humidity: 0 to 90% non-condensing

Connections: Screw terminals accept 12 to 22 AWG wire

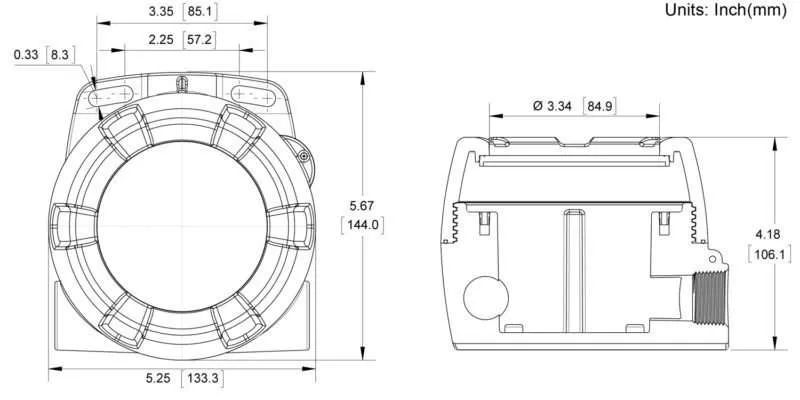

Enclosure: NEMA 4X, IP65 plastic field enclosure. Color: grey. Material: Polycarbonate with UV Stabilizer. Three ¾” NPT threaded conduit openings. Two ¾” NPT plastic conduit plugs, with 1.29″ wrenching flats and a screwdriver slot, are included.

Mounting: May be mounted directly to conduit. Two slotted flanges for wall mounting or NPS 1½” to 2½” or DN 40 to 65 mm pipe mounting.

Overall Dimensions: 5.67″ x 5.25″ x 4.18″ (W x H x D) (144 mm x 133 mm x 106 mm)

Weight: 1.65 lbs (26.4 oz, 0.75 kg)

Warranty: 3 years parts and labor

Input

Input range: 4-20 mA

Accuracy: ±0.03% of calibrated span ±1 count, square root & programmable exponent accuracy range: 10-100% of calibrated span.

Temperature Drift: 50 PPM/°C from -40 to 75°C ambient

Decimal Point: User selectable decimal point

Calibration Range: An error message will appear if input 1 and input 2 signals are too close together. Input Range: 4-20 mA. Minimum Span Input 1 & Input 2: 0.10 mA

Maximum Voltage Drop: 3.0 VDC @ 20 mA without loop-powered backlight. 6.0 VDC @ 20 mA with loop-powered backlight

Equivalent Resistance: 150 Ω @ 20 mA without loop-powered backlight. 300 Ω @ 20 mA with loop-powered backlight

Input Overload: Over current protection to 2 A max.

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

External Loop Power Supply:

| Voltage Range | Maximum Power |

| 9-30 VDC | 9 VDC | 12 VDC | 24 VDC | 30 VDC |

| | 0.2 W | 0.25 W | 0.5 W | 0.75W |

Open Collector Output (-0L1 skus Only)

Rating: Isolated open collector, 30 VDC @ 150 mA max.

Alarm Output: Assign to level or volume for high or low alarm trip point.

Deadband: 0-100% FS, user selectable

Acknowledge: Front panel ENTER button and external RESET terminals resets output and screen indication.

Application

Input Signal Conditioning

Live Input Calibration

In lieu of meter scaling, the meter can be calibrated with a precision signal source. While applying a precision signal, the relative scale value is entered via the front panel. This is done at any two points along the scale. Using this method, the operator can set a “best fit straight line” for non-linear input spans.

Multi-Point Linearizer

Up to 32 linearization points can be selected under the Linear function. The multi-point linearization can be used to linearize the display for non-linear signals such as those from level transmitters used to measure volume in odd-shaped tanks or to convert level to flow using weirs and flumes that require a complex exponent. These points are established via direct entry (SCALE) or with an external calibration signal (CAL).

Square Root Extraction

The square root extraction function displays flow rate by extracting the square root from a differential pressure transmitter signal. The user selectable low-flow cutoff feature gives a reading of zero when the flow rate drops below a user selectable value.

Programmable Exponent

The programmable exponent function is used to linearize the level signal in open channel flow applications using weirs and flumes and display flow rate and units of measure.

Connections

Dimensions