Steam is a crucial and valuable resource used in many industries, including power generation, energy storage, food manufacturing, and laboratory applications. Its unique properties allow for precise temperature control in critical processes, making it a clean and reusable energy source. Steam has been essential since the invention of the first commercial steam engine in the 1700s.

To maximize the benefits of steam, it must be effectively managed and controlled. A key aspect of steam efficiency is the ability to capture and reuse the hot water condensate that forms when steam cools and turns back into liquid. This condensate is beneficial because it retains sensible heat, which can represent 20-30% of the original steam energy. By returning this condensate to the boiler, less energy is needed to generate more steam, which also decreases the amount of fresh boiler make-up water required. This leads to a smaller carbon footprint and savings on utility and water treatment costs.

Many people recognize the importance of accurate steam measurement. It is essential for billing in facility management, departmental cost analysis, enhancing manufacturing efficiency, and minimizing costs related to expensive equipment and leaks.

In addition to precise steam measurement, tracking the energy content of the condensate returning to the boiler gives users a complete picture of energy usage in the boiler system. This information is crucial for organizations aiming to manage their Carbon Tax obligations and can lead to significant savings in both capital costs for new equipment and ongoing energy expenses. Many governments provide tax incentives for companies that implement high-efficiency metering systems, distinguishing between energy used for production and energy used for heating. This is particularly relevant for condensate energy, as it is often used for heating when it returns to the boiler.

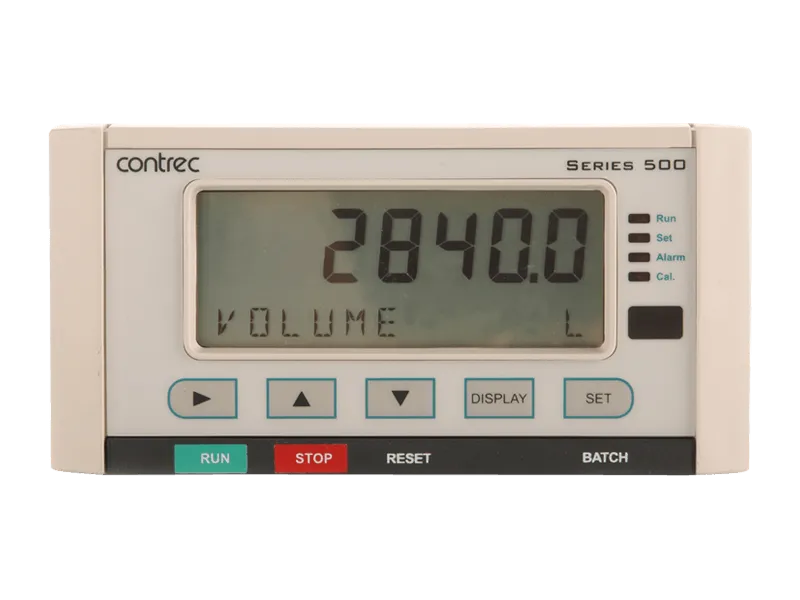

The Contrec 515-CS02 Steam to Condensate Flow Computer receives signals from the steam flowmeter (such as a vortex meter), along with temperature and pressure readings from the steam pipeline and temperature data from the condensate return line. It calculates steam flow and energy based on IAPWS industrial formulation tables, making it suitable for both saturated and superheated steam. This flow computer provides measurements of volume, mass, and net energy content for both steam and condensate. This allows users to accurately assess total system energy and differentiate between energy used in production processes and energy used for heating systems. Several governments offer tax incentives for companies that can clearly demonstrate their steam usage allocations.

In addition to offering a local display and alarms for all process parameters, the instrument also transmits this data via Modbus RTU communication. This enables integration with Contrec’s DataMod software tool or direct connection to building management systems or SCADA packages.