The Precision Digital PDW90 is a durable and customizable wireless bridge designed for point-to-multipoint communication. It provides a flexible solution for transmitting analog, digital, or Modbus® signals from one location to another. With modular input/output cards and expandable field units, the PDW90 can be tailored to fit any wireless application.

Ordering the PDW90 is straightforward, and configuring it is a breeze. You can choose from preassembled kits or individual modular components. Plus, it comes with a satisfaction guarantee—if it doesn’t meet your needs, you can return it hassle-free. For installations requiring longer distances, a wireless survey tool is available to ensure your setup will work effectively from the start.

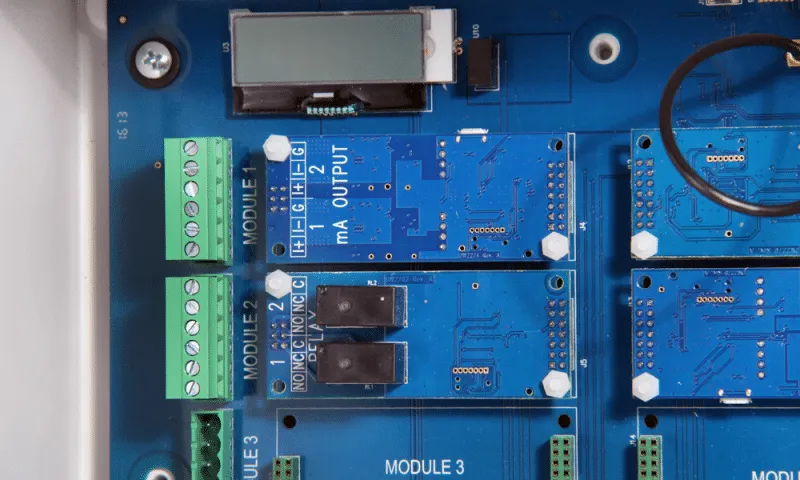

The field units can accept various inputs, including analog, discrete, or Modbus®, and they wirelessly transmit these signals to the PDW90 base station. The base station can then recreate these signals using its built-in RS-485 or analog and digital I/O cards. It can also be programmed to activate relays or send analog/digital signals back to the field units. Simply place the field units near your process signals and the base station in your control room.

Additionally, the PDW90 offers fixed or remote antenna modules along with a variety of accessories, such as mounting kits, antenna-related tools, and repeaters. You can attach the antenna directly or place it remotely, and high-gain directional antennas are also available for enhanced performance.