Running out of space in your control panel?

Selecting the right signal conditioner is about more than just converting 4-20mA signals. It is about panel space, wiring efficiency, and ease of maintenance.

At Celectric Sdn Bhd, we specialize in MTT (Ms. System) signal conditioners from Japan. However, engineers often ask us: “What is the difference between the MS3100, MS3700, and MS3000 series?”

In this guide, we break down the three most popular mounting styles to help you decide which one fits your project.

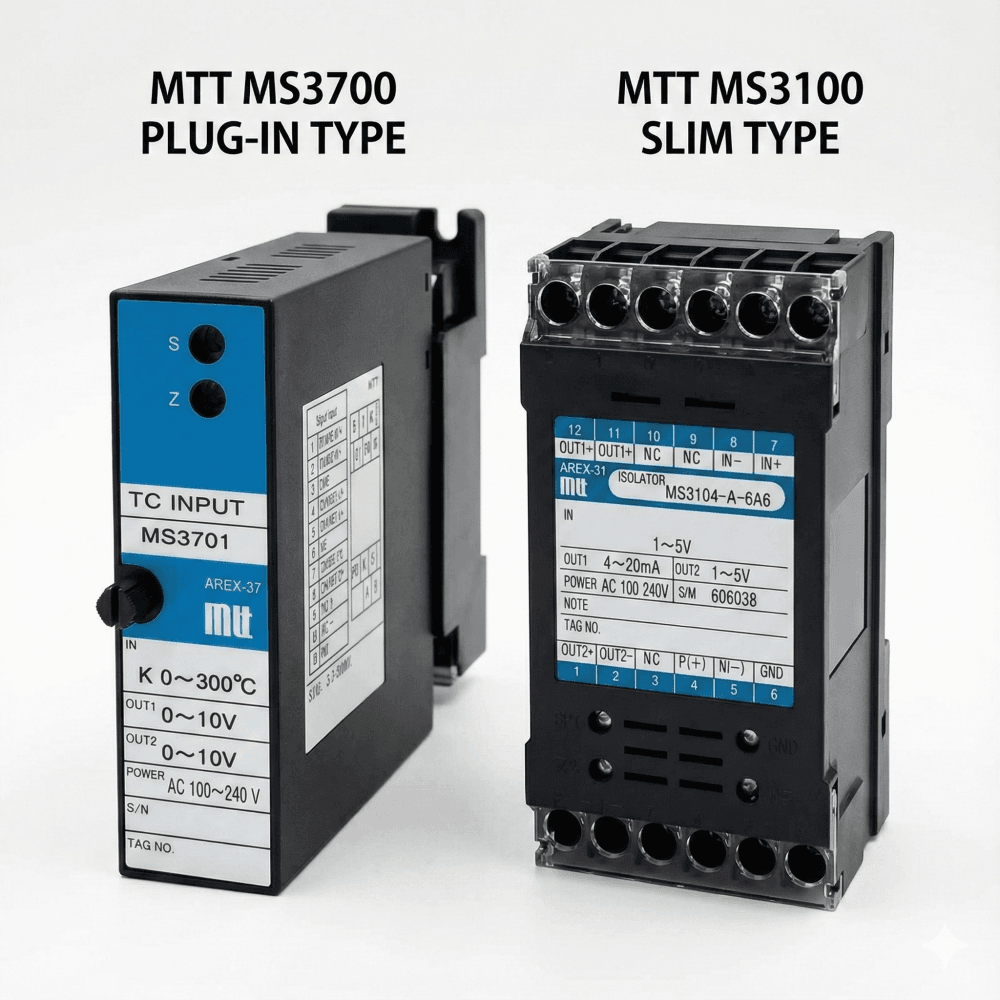

1. MTT MS3100 Series: The Space Saver (Terminal Block)

Best For: Small PLC panels and tight retrofits.

If you are counting every millimeter of DIN rail space, the MS3100 Series is your winner. These Ultra-Slim Signal Conditioners are designed to look and feel like a standard terminal block.

- Ultra-Slim Profile: At only 6.2mm wide, you can fit dozens of units in the space of a few standard isolators.

- Terminal Block Design: No need for a separate base socket. You wire directly into the unit (Screw or Spring Clamp options).

- Cost-Effective: Often the most budget-friendly option for simple isolation tasks.

👉 View MS3100 Series Specifications & Models

2. MTT MS3700 Series: The Maintenance Favorite (Plug-in Type)

Best For: General instrumentation and critical processes.

The MS3700 Series is the industry standard for reliability and ease of use. Unlike the terminal block style, these units consist of two parts: the Main Unit and the Base Socket.

- Hot-Swappable: If a unit fails (rare for MTT!), you can pull the main body out of the socket without disconnecting a single wire. This means zero downtime for wiring errors during maintenance.

- Versatility: Offers the widest range of functions, including intricate math functions, potentiometer inputs, and distributors.

- Power Options: Available in AC (85-264V) and DC (24V) versions.

👉 View MS3700 Series Plug-in Conditioners

3. MTT MS3000 Series: The High-Density Powerhouse (Rack Mount)

Best For: DCS upgrades, Central Control Rooms, and Large Scale Plants.

When you are building a massive control room for a chemical plant or power station, you don’t want individual DIN rail mounts. You need the MS3000 Rack Mounting System.

- Chassis Mounting: Fits up to 16 units in a standard 19-inch rack chassis.

- Shared Power: You only need to power the rack (using the MS3900 power unit), which distributes power to all 16 modules via the backplane. This reduces wiring time by 50%.

- Clean Organization: Keeps large-scale instrumentation clean, organized, and professional.

👉 View MS3000 Rack Mount System

Comparison Table: Which Series Do You Need?

Use this quick reference table to select the right series for your application.

| Feature | MS3100 Series | MS3700 Series | MS3000 Series |

| Mounting Style | DIN Rail (Terminal Block) | DIN Rail (Base Socket) | 19-Inch Rack Chassis |

| Unit Width | 6.2mm (Ultra Slim) | 29mm (Standard) | High Density Rack |

| Wiring Method | Direct to Unit | Screw Terminal Base | Backplane Connector |

| Maintenance | Requires unscrewing wires | Hot-Swap (Plug-in) | Hot-Swap (Plug-in) |

| Power Supply | 24V DC Only | AC or DC Options | Shared Rack Power |

| Best Application | Tight PLC Cabinets | Critical Process Control | Large DCS Projects |

| Link | Shop MS3100 | Shop MS3700 | Shop MS3000 |

Need help selecting the right model?

Whether you need a single isolator or a full rack system, our engineering team in Penang can help you select the correct MTT model number.

Contact Us for a Quote or WhatsApp Our Technical Team.