A loop powered meter is one of the simplest and most cost-effective ways to display a single process variable. It integrates easily into existing 4–20mA current loops, needs no external power, and reduces installation and wiring costs — making it ideal for industrial applications in Malaysia.

What Is a Loop Powered Meter?

A loop powered meter connects directly to a 4–20mA current loop, the standard signal used to transmit process data like flow, pressure, temperature, or level.

It draws power from the loop itself, so it doesn’t need a separate power supply.

How It Works:

The 4–20mA loop carries both signal and power.

The meter reads the signal to display the process value.

Only two wires are needed — simplifying installation.

Why It’s Popular:

No extra power wiring

Low cost and easy to retrofit

Reliable even in remote or hazardous areas

How to Add a Loop Powered Meter to Your System

Adding a loop powered display is simple.

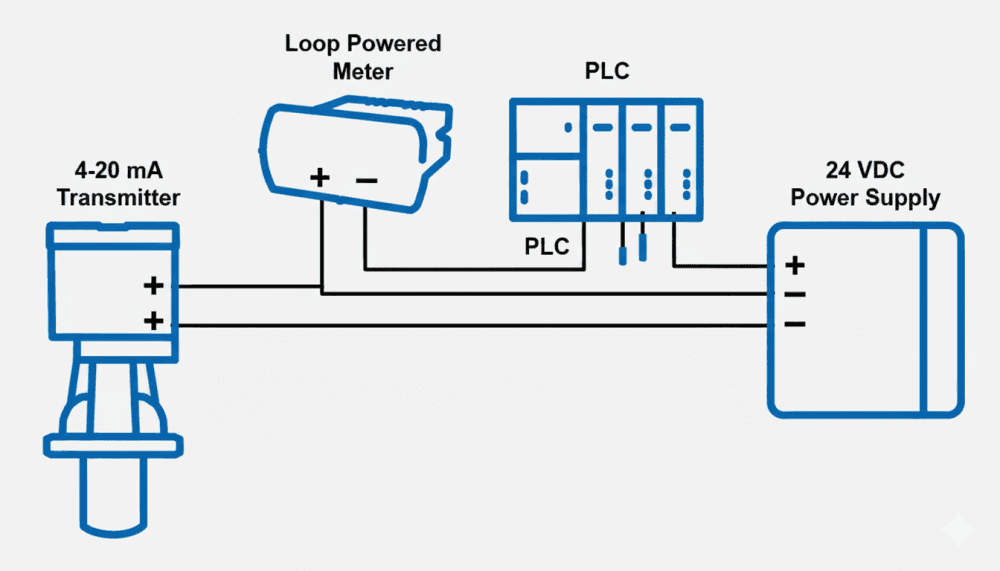

Break the existing 4–20mA loop at your desired point and wire the loop powered meter in series.

In a typical setup:

A 24VDC power supply powers the 4–20mA transmitter.

The loop powered meter reads the same current to show the live process value.

This is especially useful when transmitters are installed in hard-to-reach areas — such as tank tops, pump pits, or outdoor installations.

A remote loop powered meter lets you see readings safely from a convenient location.

✅ Key Benefits of Using a Loop Powered Meter

Easy Integration: Works with any standard 4–20mA loop

No Local Power Required: Uses the existing loop current

Simple Wiring: Only two connections needed

Low Installation Cost: No need for new power lines

Compact & Reliable: Ideal for panel or field mounting

Hazardous Area Approved: Many models certified as Intrinsically Safe (I.S.) or Non-Incendive (N.I.)

🧰 When Should You Use a Loop Powered Meter?

Choose a loop powered meter when:

You only need to display one process variable (like flow or pressure)

The signal source is a 4–20mA current loop

No external power source is available

The site is remote or in a hazardous area

Because they consume very little power, loop powered meters are perfect for intrinsically safe installations in hazardous environments such as oil & gas plants, refineries, or chemical facilities.

🔋 What Powers a Loop Powered Meter?

A loop powered meter gets its power from the same 4–20mA current loop that carries the process signal.

The current that represents the measurement also powers the display — so there’s no need for separate power lines or batteries.

This self-powered design makes it:

Ideal for remote locations

Safe for hazardous zones

Highly energy-efficient

⚖️ Loop Powered vs Line Powered Meters — What’s the Difference?

Both loop powered and line powered meters are used to display process data, but they differ in power source, wiring, and functionality.

| Feature | Loop Powered Meters | Line Powered Meters |

|---|---|---|

| Power Source | Powered by 4–20mA loop | External power supply |

| Wiring | Two-wire connection | Three or four wires |

| Display Type | LCD (low power) | LED (bright, high power) |

| Transmitter Power Output | No | Yes (can power sensors) |

| Cost | Lower | Higher |

| Functions | Basic display | Alarms, relays, serial output |

| Best For | Existing loops | New installations |

| Hazardous Area Approvals | Easier compliance | Limited options |

In Short:

Loop powered meters = simple, low-power, retrofit-friendly

Line powered meters = feature-rich, suitable for complex systems

💡 Why 4–20mA Current Loops Are So Reliable

The 4–20mA signal is the backbone of industrial control systems.

It’s preferred because:

Current doesn’t degrade over long cables

Easy to detect open or failed loops (since 0mA = fault)

Resistant to electrical noise

Compatible with almost any PLC or display

A standard 4–20mA loop includes:

DC Power Supply (24VDC)

Transmitter or Sensor

Receiver (e.g., Loop Powered Meter)

This simple series circuit transmits process data accurately — even over long distances.

🏭 Where to Use Loop Powered Meters in Malaysia

Loop powered meters are ideal for:

Water treatment plants

Chemical processing lines

Oil and gas facilities

Food and beverage systems

General manufacturing and automation

They help operators view live process readings in safe, convenient locations — even when transmitters are installed far away.

🔧 Final Thoughts

A loop powered meter offers a practical, low-maintenance way to display real-time process values from any 4–20mA transmitter.

It’s cost-effective, reliable, and simple to install — perfect for Malaysia’s diverse industrial environments.

If you’re upgrading or troubleshooting your process control system, consider loop powered meters from trusted brands like Contrec, Precision Digital, or Adtek, available through Celectric Malaysia.