In any industrial plant that handles flammable gases, vapors, or combustible dust, safety is the top priority. Monitoring liquid levels in these hazardous locations requires specialized sensors that won’t become an ignition source. Two of the most trusted safety standards for these sensors are Explosion-Proof and Intrinsically Safe.

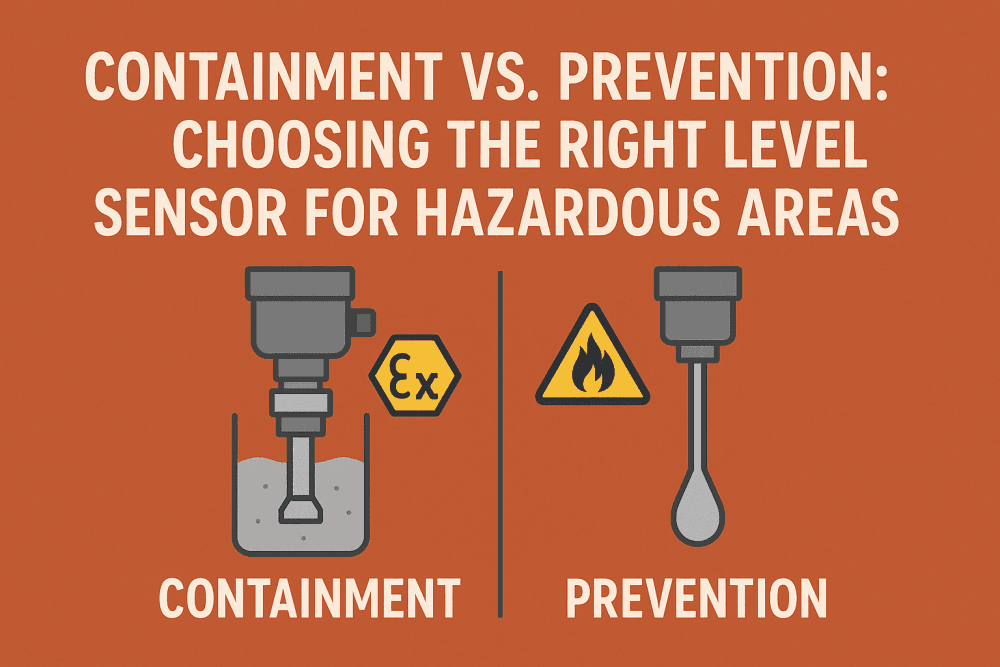

While both are designed to prevent catastrophes, they achieve safety in fundamentally different ways. Understanding this difference—containment versus prevention—is key to selecting the right solution for your application.

The Explosion-Proof (EP) Approach: Containment

An explosion-proof sensor is built on the principle of containment. It is designed with an extremely robust and heavy-duty enclosure, typically made of cast aluminum or stainless steel.

The core idea is not that an electrical fault or spark can’t happen inside the sensor. Instead, it assumes that it could happen. If a spark were to ignite flammable material that has entered the sensor’s enclosure, the resulting internal explosion is completely contained within that housing. The carefully engineered seals and flanges of the enclosure cool and vent the hot gases, preventing them from igniting the much larger hazardous atmosphere outside the sensor.

Explosion-Proof sensors are often chosen for:

Oil and gas facilities, such as monitoring fuel levels in storage tanks.

Chemical processing plants where volatile substances are present.

Mining operations that require rugged equipment in dusty or gaseous environments.

The Intrinsically Safe (IS) Approach: Prevention

Intrinsic Safety works on the principle of prevention. Rather than containing an explosion, an IS system is designed to prevent one from ever happening in the first place.

This is achieved by ensuring the electrical energy in the sensor circuit is far too low to create a spark or generate enough heat to ignite the hazardous atmosphere. An Intrinsically Safe solution is not just a sensor—it’s a complete system. It involves using a standard low-power sensor in the hazardous area and connecting it via an IS barrier or Safe-Pak® relay located in a safe area. This barrier acts as a gatekeeper, limiting the voltage and current flowing to the sensor to a level that is certified as safe.

Intrinsically Safe systems are ideal for:

Wastewater treatment plants for chemical dosing and level monitoring.

Agricultural settings like grain silos, where combustible dust is a major concern.

Advanced applications like monitoring cryogenic hydrogen in fuel systems.

Which Safety Method is Right for You?

Choosing between Explosion-Proof and Intrinsically Safe depends on your specific needs, budget, and maintenance procedures. EP solutions are self-contained and rugged, while IS systems can offer more flexibility and potentially allow for live maintenance without shutting down power.

The ultimate goal is the same: to ensure the safety of your personnel and facility. By understanding the core difference between containing an explosion and preventing one, you can make a more informed decision for your hazardous area level monitoring needs.